Good morning and welcome back to Friday Thread. Starting Torsa from the ground up with very little capital was a huge challenge. It did, however, teach me some crucial insights, tips and tricks into building a collection using a business-first mindset. Let’s dive in.

When I started Torsa, I launched with five products. These were a performance t-shirt, merino wool t-shirt, a pair of training shorts, technical bottoms and a 1/4 zip sweatshirt. In hindsight, this was a big mistake.

From the outside looking in, five products may seem like a small range. However, when you’re a start-up apparel brand without external investment, five products is anything but small.

This article aims to explore how to develop your first collection with a business brain on. What you’ll come to realise as a founder of an apparel brand is that taking a business-first approach shouldn’t just be a consideration, but instead, may be the difference between survival and not in the early years.

When I first started working with a designer for Torsa, I came to her wanting to create a well rounded capsule collection which covered all the training essentials for the modern man. This included;

-

high-performance t-shirt that could handle the toughest of workouts.

-

the temperature regulating Merino wool t-shirt for running or lighter workouts

-

a well-rounded and durable training short that was comfortable and highly technical

-

a 1/4 zip sweatshirt for comfort that could be worn to-and-from the gym and seamlessly transition into your everyday wardrobe

-

a technical tracksuit bottom that could be used for training but also as a smart looking trouser for Sunday brunch and coffee

If I review the list today, it’s abundantly apparent I was trying to cover too many things. Five different products with too much variance in their end use. The training t-shirt and training shorts worked seamlessly together, and it’s no surprise then that they were the best selling pair of products bought by far. In fact, if I relaunched today, I would consider launching those two products and nothing else.

The most important aspect of your business, therefore, isn’t simply how good your product looks, but also the economics behind creating it. Building five completely unique products means more design costs, development costs, sourcing costs, sampling costs, logistics costs, the list is endless. So, what would I do differently if I launched another sportswear brand? Well, first I’d look at the fundamentals of building the products itself.

When I first started Torsa, I didn’t really have a grasp of the financial fundamentals when it came to developing products. I sought out the advice of someone who had started an apparel business to understand what margins I should aim for.

Having worked in fashion as a buyer before, I had an understanding of wholesale price to retail price, but less so the cost price of actually building products and its relationship with retail price.

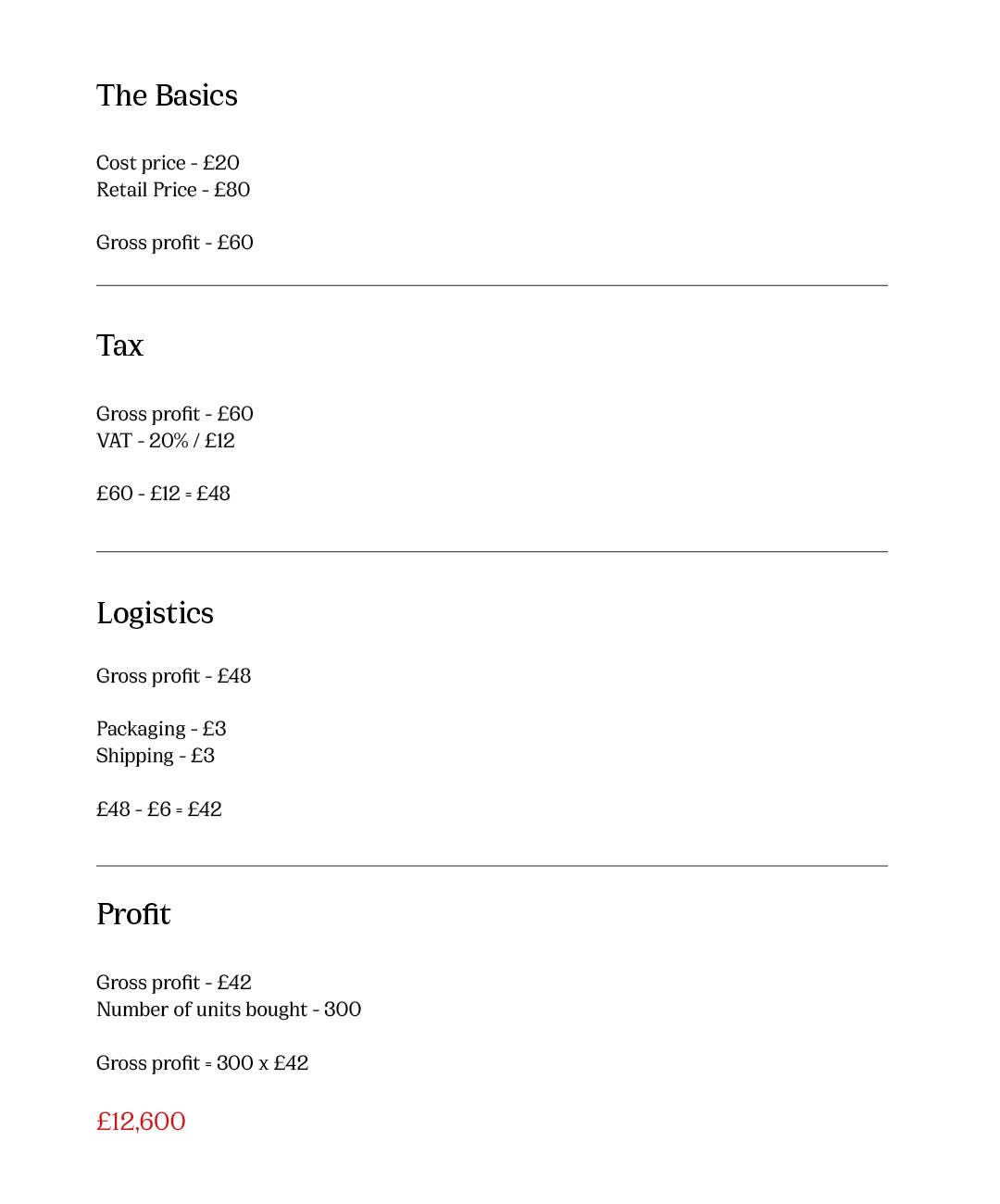

I was told, maybe surprisingly at the time, I should be aiming for an 80% gross profit margin. I was taken aback by just how big a margin that was. Essentially if I created something for £20.00, I’d be selling it for £80.00. It seemed like a huge margin at the time, but I quickly came to realise that in order to survive as a business, this was a necessity.

Whilst as a customer you might be surprised that you’re £80.00 pair of shorts is costing £20.00 to produce (and likely less), it’s important to understand the factors that offset this margin. This £60.00 gross profit isn’t really profit at all. I’ve broken down in very simple terms just how this profit gets diminished below;

As you see, I have based this off building one product and then creating 300 units of this product, which as a start-up apparel brand, is a pretty realistic minimum order quantity.

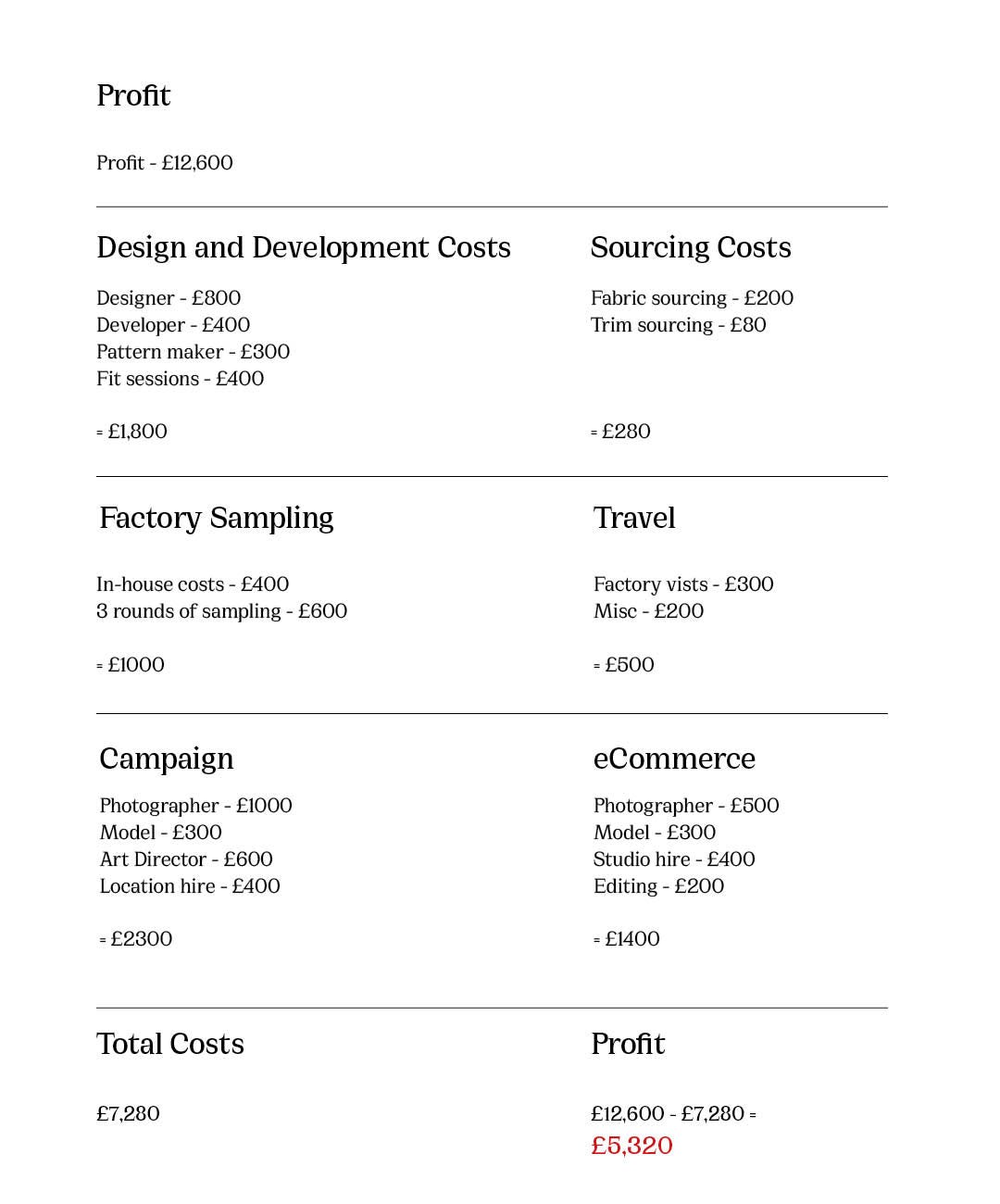

So, solely looking at it from a product standpoint, and not factoring in other costs, we’re looking at a £12,600 profit for that one product. This may sound okay until you realise this isn’t profit at all. Let’s break it down further from a cost standpoint related to building that one product.

The scary part about this is that I haven’t even factored in the cost to acquire that customer to sell the product. Paid ads, email marketing costs, influencer marketing, SEO, press etc. I also haven’t even touched on the daily running of the business; rent, utilities, salary, insurance, they all have to be covered and the only way to cover them is by selling product.

If you take anything away from today’s article, let it be this breakdown. It does seem scary, and in all honesty, it is. However, remember that once that one product has been created, if you sell more units at real volume, that is where the profits begin to flow.

In the examples above, I have broken it down from a viewpoint of creating 300 units, which is very realistic for a start-up. But, let’s say you develop a product so good and market is so well that you sell 1,000 units instead of 300 units. Your costs in the second infographic stay the same for building that product (more or less), so we’d be looking at a profit of 1,000 x 42 = £42,000 – £7,280 = £34,720. A formidable difference.

This nicely leads us onto our second point, building one thing, and doing it exceptionally.

I mentioned before that when I started Torsa I wish I focused and launched with just one or two products. There are many reasons why building using this approach is beneficial for a start-up apparel businesses.

Firstly, whatever money you do have (or have raised) can be laser focused on the design and development of one or two products. Launching with five products, like I did with Torsa, meant that I had to split my time, resources and development efforts across multiple products. Not only did this mean that the costs were so much higher, the time it took to launch followed suit.

When you’re developing five individual products, it means that you have to build five individual pieces from scratch. This means you’re paying a designer more money to design, a pattern maker more money to build patterns, and a developer more money to develop the product, update tech packs and so on.

Sourcing also becomes incredibly expensive. With one product, you may only need to source and purchase one fabric. With five unique products, you have to source and purchase five or more fabrics. Sourcing, testing and sampling five fabrics becomes incredibly expensive and time consuming. You then need to meet the MOQ’s for these fabrics, and if you don’t, you will likely have to pay a surcharge, making your final garment cost higher and ultimately your margin smaller.

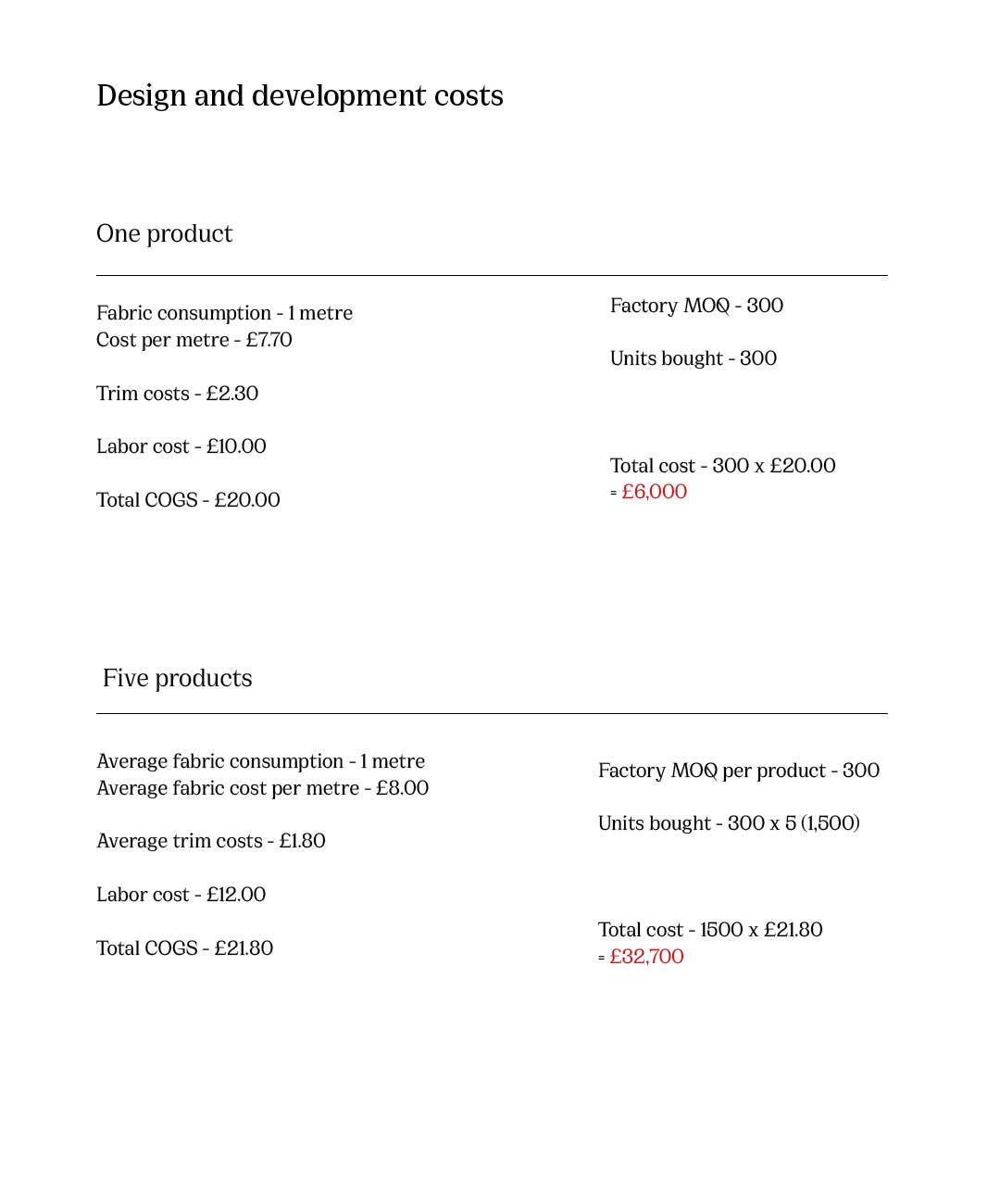

Remember, you also have to meet MOQ’s with your factory. Let’s look at a breakdown per style, assuming your MOQ’s are 300 units.

As you can see, by building a collection of products, the costs start to compound. There is simply no good way of getting around this. Factories are strict when it comes to MOQ’s, and they always base it per individual product, and not order.

You can start to see why, as a start-up business, developing a whole collection is so difficult (and expensive).

I spoke about the power of one (or two). I mention “or two” because I have seen this approach successfully executed before. When Ten Thousand launched back in 2015, they started with just a training t-shirt and pair of shorts. They stripped everything back and delivered a combination of products that worked seamlessly together. This allowed founders Keith Nowak and Eugenio Labadie to focus all their efforts on two styles, without having to compromise.

Why this approach often works is that you are putting your design and development efforts into less things. It means you can focus on sourcing and testing better fabrics, developing more unique trims, optimising fit through pattern making and fit sessions, and putting the product through more rigorous field testing.

What is also allows you to do is focus all your marketing efforts into selling one (or two) products. In the case of Torsa, I was having to split my efforts to reach different audiences. For example, the Merino T-shirt and performance T-Shirt were appealing to different audiences, so I was having to split resources across these two customer profiles, and therefore, wasn’t optimising my strategy and it ended up costing me more to acquire customers.

If I had focused my efforts into launching just one product, our lilac Onyx T-shirt for example, would I have made a lot more profit to reinvest into the company in the early months and years? Well, knowing that the Onyx T-shirt sold at a ratio of 5-to-1 against all other products, the data would suggest, absolutely.

Unlike other industries, in apparel, I understand there are certain challenges launching with one product. Not from a development standpoint, but more so from a consumer purchasing standpoint.

Whilst there are a host of industries that lend themselves to single product launches (tech, footwear, cars, food), with apparel, it’s very difficult to make an impact with just a single product. This is because there really isn’t that much room to innovate. If you launch a running t-shirt, what really is going to be a determining factor for someone to purchase it. There are hundreds of fantastic running t-shirts on the market, so even if you launch the so-called ‘best’ running t-shirt on the market, is it really enough?

However, if you launched a trail running shoe with a completely new innovative fabric and sole which rivals Vibram, there is certainly more likelihood that trail runners might purchase them, because it’s innovative and unique.

I’ve spoken about how Ten Thousand launched with just two products, and therefore minimising their design, development, and sourcing costs in the beginning. If you build a big collection and commit to many units, unless you have a huge marketing budget and a strategy to generate sales, as a small business, you simply won’t sell the units you need to survive. The best advice I can give you in the early days is to keep your collection as streamlined as possible. I’ve discussed the challenges of creating just one product as an apparel brand, so let’s take a look at a strategy that will allow you to launch multiple products, but crucially, limit your costs.

New brands that are looking to build a collection should be looking at streamlining their offering. Design and development is an incredibly expensive process, both as a new start-up brand, and as a more established brand.

Looking at ways to minimise the costs of design, development, sourcing and sampling should be a key consideration when you’re building a collection. One way to achieve this is through product consolidation.

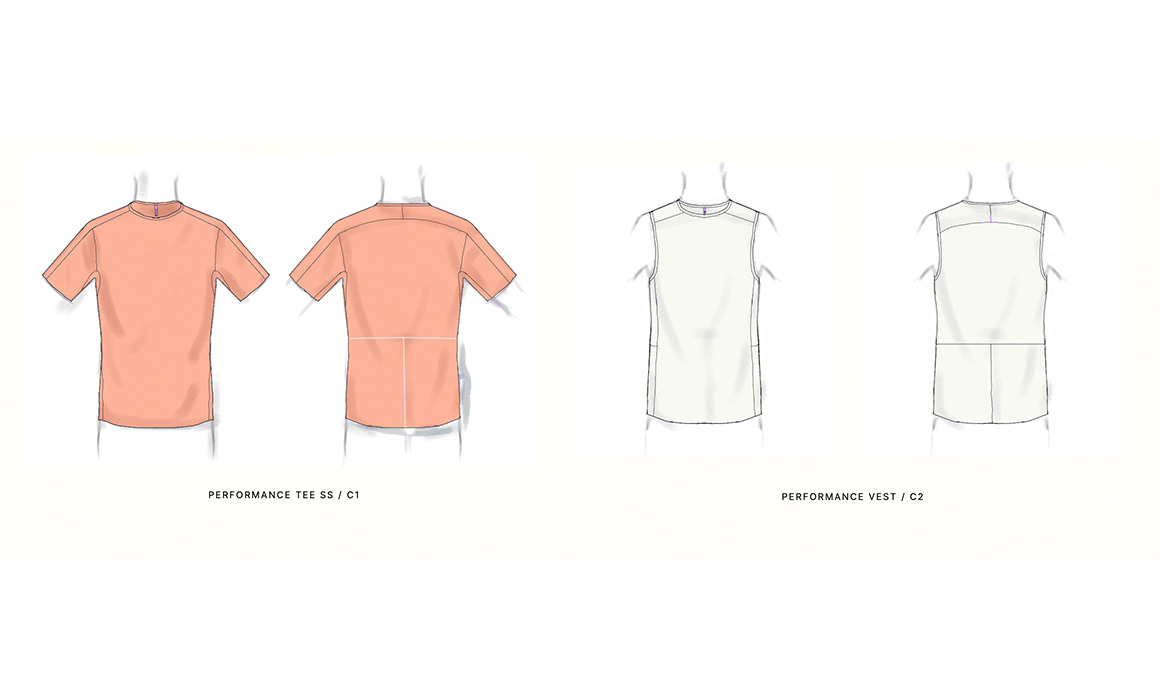

The term product consolidation refers to building two unique products that use the same design blueprint and foundation. Here are a list of a few examples below;

-

Short sleeve and long sleeve t-shirt

-

Short sleeve t-shirt and vest

-

5” training shorts and 7” training shorts

-

Running short without liner and running shorts with liner

The reason why this is a far more cost effective way of building multiple SKU’s is focused around a number of factors.

Let’s take a look at the examples above. You have four individual products here, but two of them are variants of the same style. Therefore, when you’re working with a designer, instead of building four completely unique products, you’re essentially building two.

The foundation is the same, but in this case, you’re adding a longer sleeve for the merino t-shirt and taking the sleeves off for the performance t-shirt to make a vest. These are simple design changes, and therefore you’re not having to pay the designer to conceptualise and design four lots of individual designs, but instead two with slight variations. This, in turn, saves you a lot of money when it comes to research and design.

Another key consideration from this is sourcing. One reason product consolidation works so effectively is because you’re minimising managing multiple processes. In the example of Torsa’s core collection, I sourced five completely unique fabrics for our products. Each product was so inherently different that in order to get the best fabric possible for end use, I ended up working with five different mills around the world. Here is a snapshot below of our core collection and the overview of fabrics used.

Working with five different mills isn’t cost effective in any way, for many reasons. One of the main disadvantages of this approach is you’re fabric per yard / metre becomes expensive, because you’re ordering small amounts of metres from different mills.

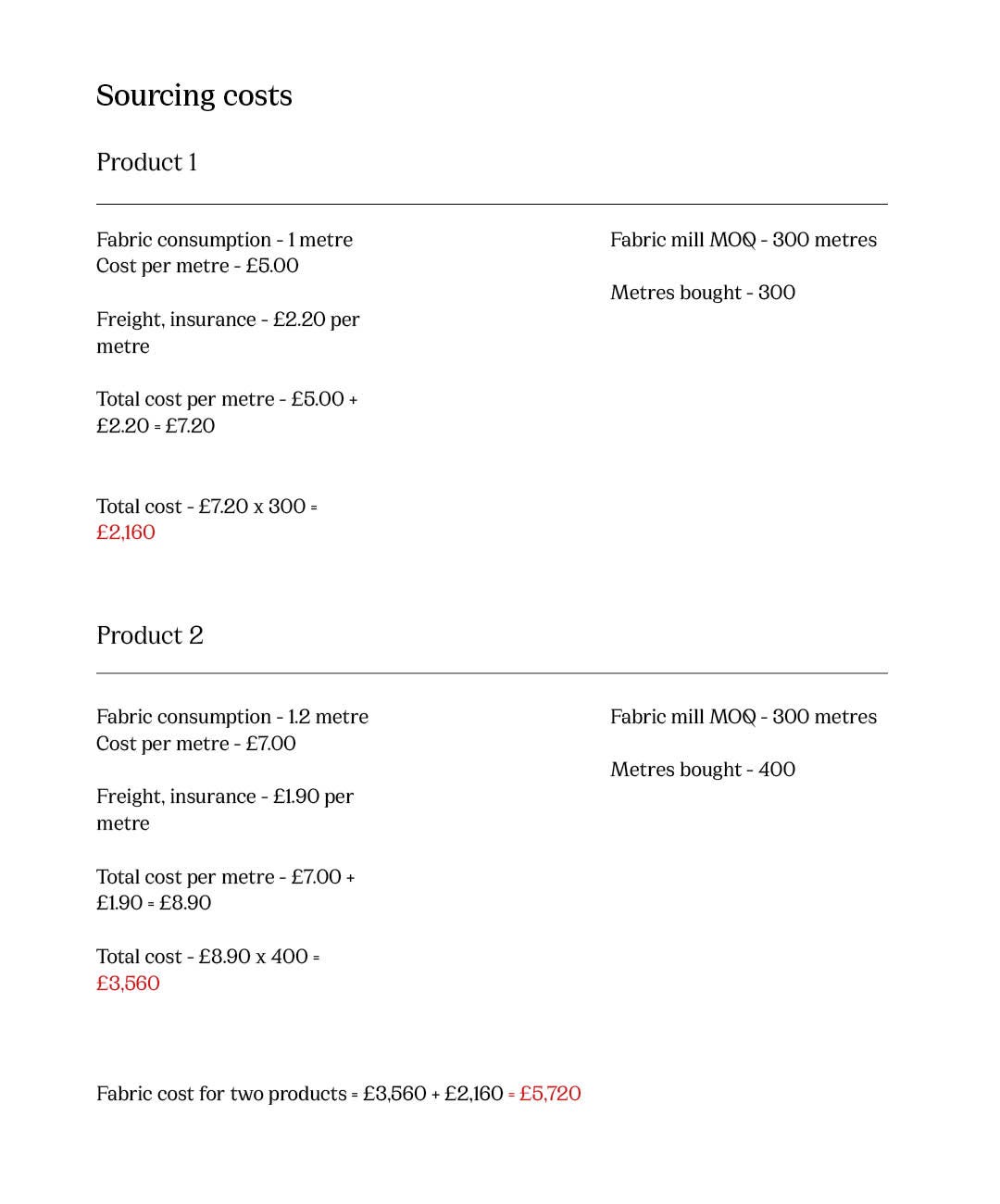

When you order fabric from a mill, you don’t just have to consider the cost per yard / metre, but also the cost of shipping that small amount of fabric from wherever it gets produced in the world to your factory. Let’s look at a breakdown below exploring both approaches;

-

Sourcing two different fabrics from two different fabric mills

-

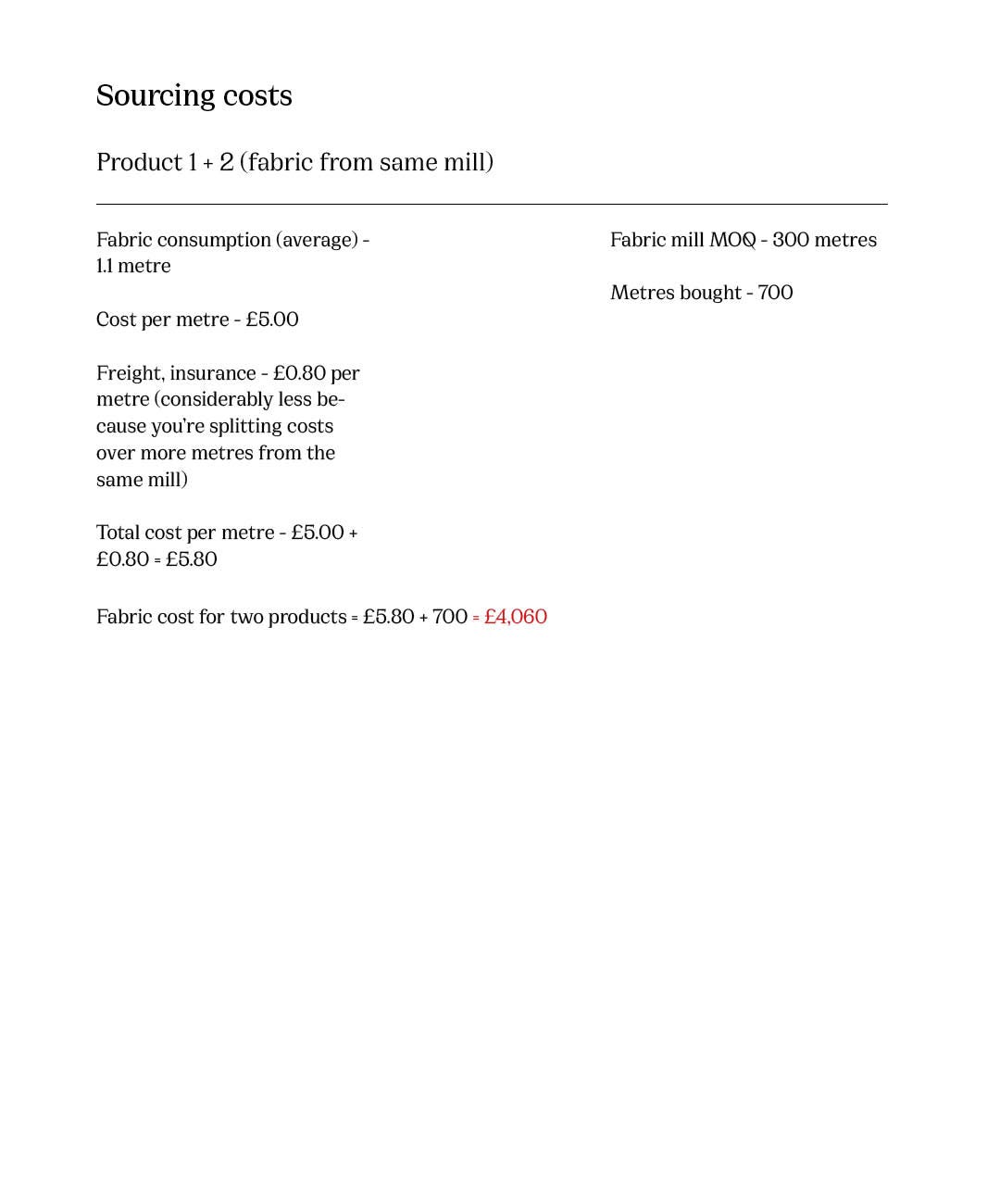

Sourcing the same fabric for two products from the same mill

As you can see, you’re saving a considerable amount on fabric by consolidating your product to just one mill. This, however, is just one of many cost savings you’ll benefit from when consolidating your product. I’ll go into more depth on this in future articles.

Product development is the real nitty gritty of taking a design and building it into a final product. It can often be exhausting and full of knock backs. However, by consolidating product, the time and resources spent on getting them to market greatly reduce.

As you can imagine, adding a longer sleeve to a t-shirt that has already been developed is far easier that creating a whole new long sleeve from scratch. The foundation – from the design to the block patterns – are already there, so turning it into a long sleeve is pretty simple.

Of course, there will be some elements of development and some alterations to the pattern, but the blueprint has already been set. Here is an example of an unreleased Merino T-shirt which we developed last year using the product consolidation approach.

As a start-up apparel or sportswear brand, your focus shouldn’t solely be on building a dream collection; economics needs to come first. Understanding the correct way to build on a budget will truly go a long way in helping you survive the early months and years of building your brand. Even if you have considerable investment, I’d still utilise an approach that minimises the stress of logistics and cost by using the product consolidation approach. Every major brand does it, and as a start-up without resources, expertise and time, it’s a critical approach.

When you’re looking at launching a brand, don’t feel like you need to cover every aspect of your customers needs. Focus on one or two things done incredibly well. You’re better of launching a short and long sleeve Merino wool t-shirt beautifully constructed, then a range of five different products that haven’t been given the same time and care.

First and foremost, margin is crucial. Reference the infographics above and start from there. Your business simply won’t survive if you don’t have the margins to scale. There may be instances where you can take a hit on margin for growth, but in my experience, that’s only applicable when you’re doing lots of volume, and have the marketing money behind you to sustain that. As a small start-up, my advice is to aim for an 80% gross profit margin, and that way, you have the foundation for scaling.

link